|

|

|

|

|

Efficient packaging is a must for any

product in this modern era. Without it, the

brand image and integrity, as well as the

quality built into the product during

manufacturing and marketing, will be lost

when it reaches the consumer. Correct

packaging is the principal way of ensuring

safe delivery of the product to the end-user

in good condition at an economic cost.

At Advanced Packaging Technology (M) Bhd, we use our

specialized knowledge and skills, as well as

specific machinery and facilities to deliver

excellence in quality and services to each

client.

|

PRINTING

|

|

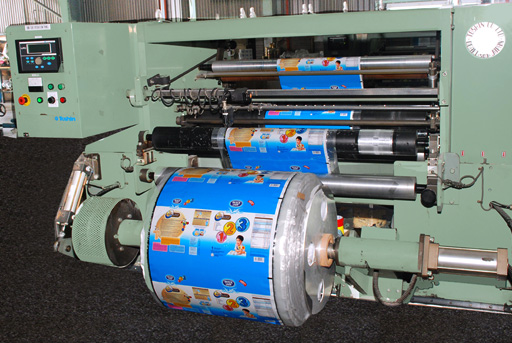

In the printing of flexible packaging

material, the rotogravure method is

particularly suited where accurate and fine

colour reproduction is desired. This process

transfers ink from an etched cylinder to the

printing material. |

|

ADHESIVE / DRY

LAMINATION |

|

To meet specific packaging requirements,

special adhesives are used to laminate two

or more substrates. The most common

applications for adhesive lamination are

metallised films – metallised CPP and

metallised polyester, among others. |

|

EXTRUSION

LAMINATION / COATING |

|

To produce double or multi-layered

material for various packaging material for

various packaging requirements, plastic

films, usually polyethylene (PE) or

polypropylene (PP) are extruded onto or

combination of paper, aluminium foil,

oriented polypropylene (OPP), polyester,

nylon and other flexible packaging

materials. |

|

SLITTING

|

|

The printed / laminated materials are

then slitted into smaller rolls according to

each client’s specifications. For this

operation skill and experience is required

to ensure a smooth and efficient utilization

of packaging lines of our clients. |

|

POUCH / BAG MAKING

|

|

To cater for "test marketing" of new

products and before investing heavily on

automatic packaging lines, Advanced

Packaging Technology (M) Bhd is able to

supply packaging materials in pouch / bag

form for manual or semi-automatic filling.

We have centre-seal, three-side seal,

four-side seal, stand and gusset pouch / bag

with optional tear-cut features. |

|

|

|

|

|